A resin 3D printer is a type of printer that uses a liquid resin material to create high-resolution 3D prints. Resin 3D printers are known for their ability to produce intricate and detailed models with smooth surfaces, making them popular among designers, artists, and engineers.

With their precise layer-by-layer curing process, resin 3D printers can create objects with fine details and sharp edges, making them ideal for applications in jewelry making, prototyping, and miniature modeling. The resin material used in these printers is typically cured using either ultraviolet light or laser technology.

By selectively curing the liquid resin, the printer builds up the model layer by layer, resulting in a solid and accurate 3D print.

Understanding Resin 3d Printing

Resin 3D printing is a revolutionary technology that allows for intricate and highly detailed three-dimensional models to be created with precision and accuracy. Understanding how resin 3D printing works and the types of resins used are essential for harnessing the full potential of this advanced printing method.

How Resin 3d Printing Works

Resin 3D printing, also known as stereolithography or SLA printing, uses a liquid photopolymer resin that is cured layer by layer using an ultraviolet light source. The build platform descends into the resin tank, where a laser or projector selectively solidifies the liquid resin, creating the desired object.

Types Of Resins Used In 3d Printing

- Standard Resins: Ideal for general-purpose printing with a balance of strength and detail.

- Tough Resins: Provide enhanced durability and impact resistance for functional prototypes.

- Flexible Resins: Offer flexibility and elasticity for applications requiring rubber-like properties.

Advantages Of Resin 3d Printing

Resin 3D printing, also known as stereolithography (SLA), is a cutting-edge technology that offers a host of advantages over traditional 3D printing methods. It utilizes liquid resin that is cured layer by layer to create highly detailed and precise 3D models. Let’s explore the key advantages that make resin 3D printing an attractive option for various industries.

High Level Of Detailing

One of the standout advantages of resin 3D printing is its ability to achieve an exceptional level of detailing. This technology allows for the creation of intricate and complex designs with a remarkable level of accuracy. Whether you’re producing small figurines, intricate jewelry, or intricate prototypes, resin 3D printing ensures that every minute detail is captured with precision and clarity. The high level of detailing makes it ideal for applications where intricate designs and fine features are crucial, such as in product development or art-related projects.

Smooth Surface Finish

The smooth surface finish is another key advantage of resin 3D printing. With this technology, you can achieve a polished and glossy surface on your 3D printed models. Unlike traditional Fused Deposition Modeling (FDM) printers that leave visible layer lines, resin 3D printing produces parts that have a smooth texture, almost resembling injection molded parts. This smooth finish not only enhances the overall aesthetics of the printed object but also reduces post-processing requirements. Whether you’re creating functional prototypes or display models, resin 3D printing delivers results that are visually appealing and exhibit a high-quality finish.

Fast Printing Speed

Resin 3D printers are known for their fast printing speeds when compared to other 3D printing technologies. The liquid resin used in the printing process allows for rapid curing, significantly reducing the overall printing time. This makes resin 3D printing well-suited for projects that require quick turnaround times without compromising on the design quality or accuracy. Whether you’re producing industrial parts or custom-made items, resin 3D printing ensures that deadlines are met without sacrificing the intricacy and detailing of your designs.

Diverse Material Options

Resin 3D printing offers a wide range of material options to suit various applications. With different types of resins available, from rigid and durable to flexible and rubber-like, you have the flexibility to choose a material that best matches your requirements. Resin materials can also be tailored to mimic the properties of specific end-use materials, allowing for functional testing and evaluation. The versatility in material selection makes resin 3D printing a versatile solution for industries ranging from automotive to healthcare, enabling the creation of prototypes, molds, and functional parts.

Conclusion

Resin 3D printing presents several advantages that set it apart from other 3D printing methods. The high level of detailing, smooth surface finish, fast printing speed, and diverse material options make it a valuable tool for various industries and applications. Whether you’re an engineer, designer, or hobbyist, resin 3D printing offers unparalleled capabilities to bring your ideas to life with precision and finesse.

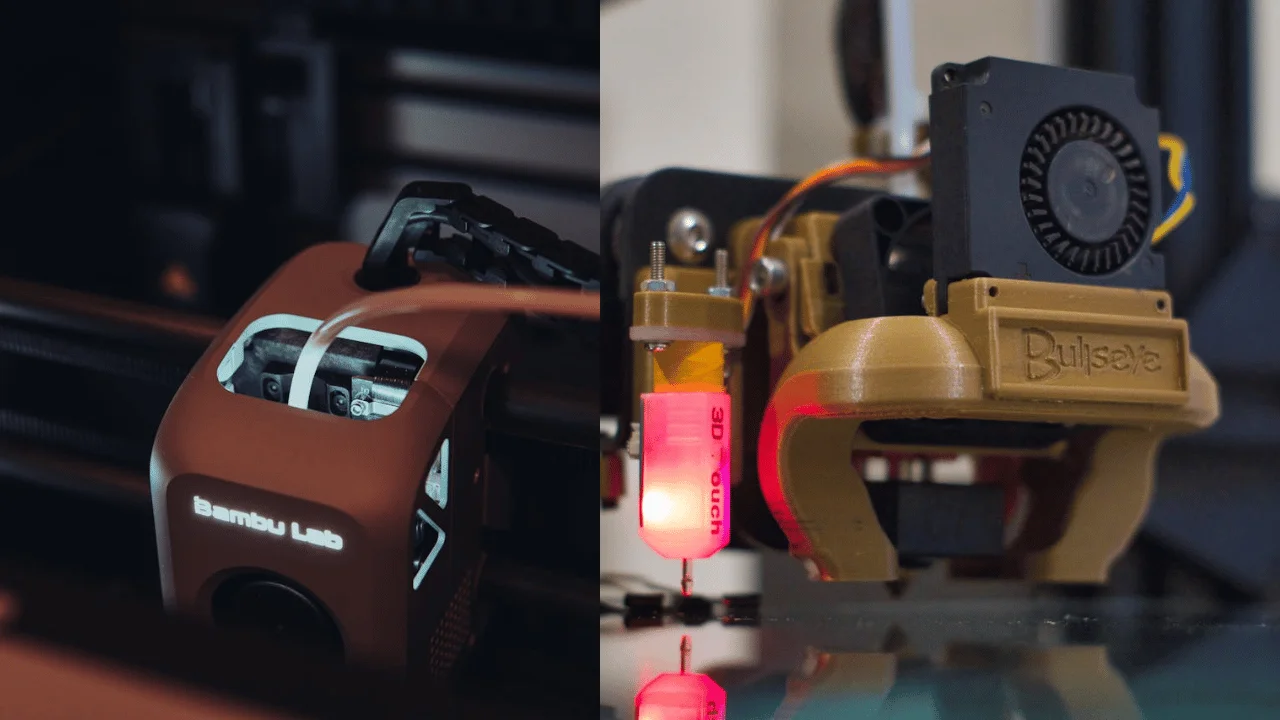

Factors To Consider Before Buying A Resin 3d Printer

Before investing in a resin 3D printer, it’s crucial to consider factors like the printer’s resolution, build volume, and compatibility with different types of resin. Understanding the printer’s maintenance requirements and the potential need for additional equipment is also essential for making an informed purchase decision.

Factors to Consider Before Buying a Resin 3D Printer In the world of 3D printing, resin printers have gained popularity for their high-resolution prints and smooth surface finish. If you are considering purchasing a resin 3D printer, it’s essential to weigh several factors to ensure you select the right one for your needs.

Resolution And Layer Height

When shopping for a resin 3D printer, pay close attention to the resolution and layer height capabilities. The resolution determines the level of detail in your prints, while the layer height affects the smoothness of the printed surface. Ensure that the printer offers high-resolution printing with minimal layer height, as this will result in finer and more precise details in your 3D prints.

Build Volume And Printer Size

Another crucial factor to consider is the build volume and overall size of the printer. The build volume dictates the maximum size of the objects you can print, so be sure to choose a printer with adequate build volume for your intended projects. Additionally, consider the physical size of the printer, especially if space is limited in your work area. In summary, before investing in a resin 3D printer, carefully assess the resolution and layer height capabilities, as well as the build volume and printer size to ensure that the printer aligns with your specific printing requirements.

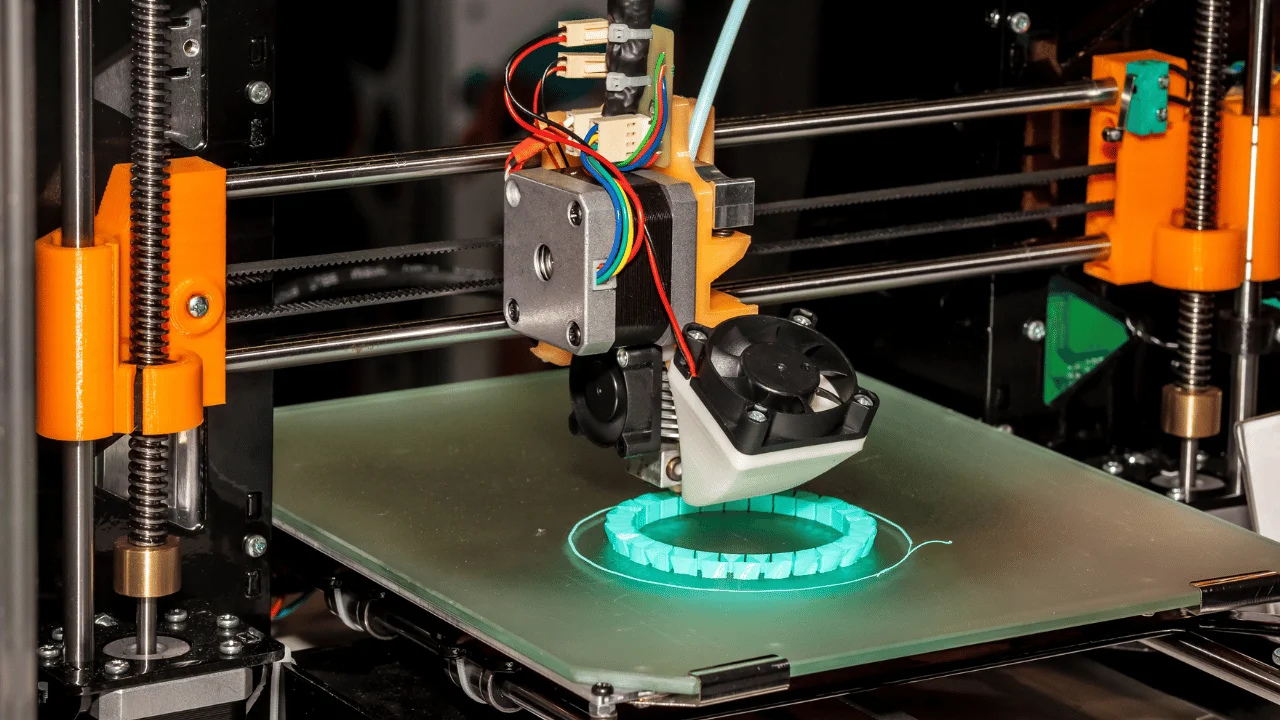

Tips For Achieving The Best Results With A Resin 3d Printer

Investing in a resin 3D printer opens up a world of possibilities for creating intricate, detailed prints. However, to ensure optimal results, proper calibration and post-processing techniques are essential. Here are some tips for achieving the best results with your resin 3D printer.

Calibrating The Printer Properly

When setting up your resin 3D printer, calibrating it properly is crucial. This ensures that the layers adhere accurately and the print quality is at its best. Pay attention to the leveling of the build plate, the exposure settings, and the Z-axis calibration to achieve precise and consistent results.

Post-processing Techniques For Resin Prints

After the print is complete, post-processing techniques play a significant role in enhancing the final outcome. Consider cleaning the print using isopropyl alcohol or specialized cleaners to remove any uncured resin. Additionally, curing the print under UV light or in a UV curing chamber helps to strengthen the print and improve its overall appearance.

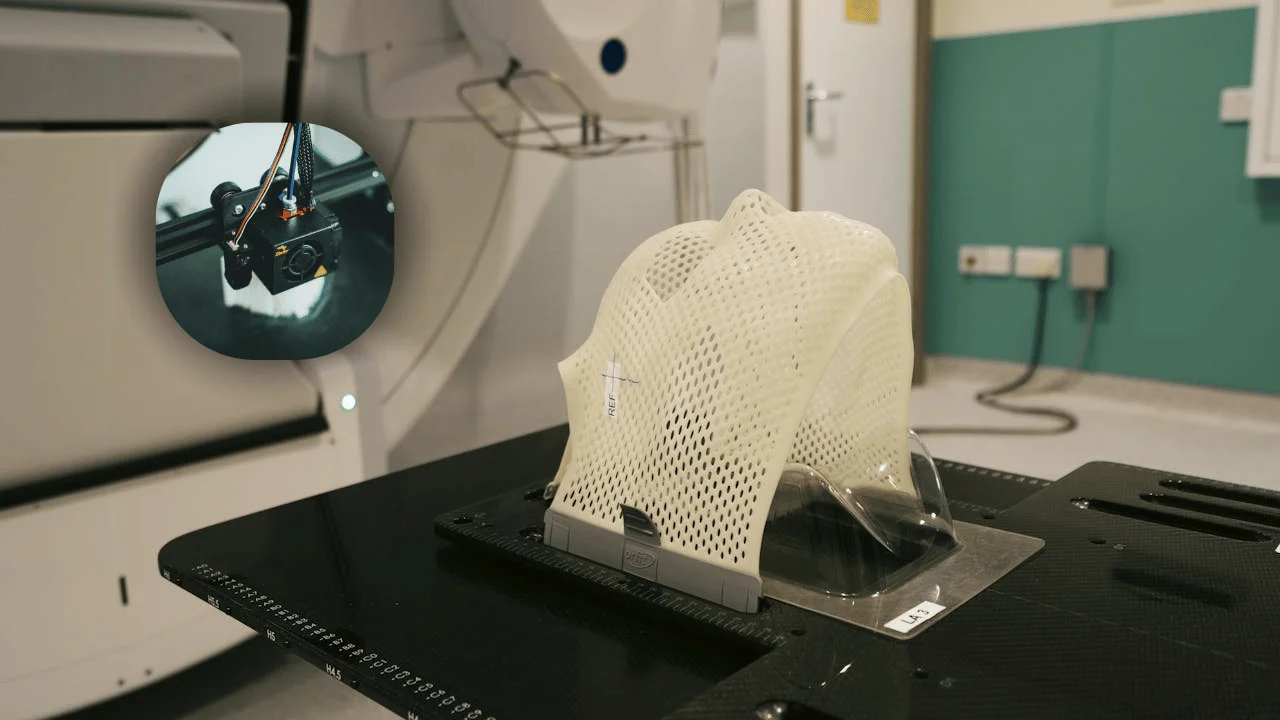

Applications Of Resin 3d Printing

Resin 3D printing, also known as stereolithography, is a revolutionary technology that has gained popularity across various industries. Its ability to create precise and intricate designs with exceptional detail has made it a game-changer in fields like jewelry making and engineering prototyping.

Jewelry Making

Resin 3D printing has emerged as a go-to method for jewelry makers who strive for uniqueness and intricate designs in their creations. With its high-resolution capabilities, resin printers can produce stunningly detailed pieces, capturing the delicate textures of gemstones and intricacies of filigree, giving jewelry artists the freedom to bring their imaginative designs to life.

Not only does resin 3D printing offer unparalleled precision, but it also allows for the production of highly customizable pieces. Designers can experiment with various shapes, sizes, and styles without the limitations of traditional manufacturing methods. This technology opens up a world of possibilities for creating one-of-a-kind accessories and statement pieces that cater to individual tastes and preferences.

Prototyping In Engineering

When it comes to engineering, resin 3D printing plays a critical role in the prototyping process. Its quick turnaround time and ability to produce complex geometries make it an invaluable tool for engineers and product developers.

With resin 3D printing, engineers can easily create functional prototypes to test and validate their designs before moving on to expensive and time-consuming production processes. The versatility of resin printers allows for the production of intricate parts and intricate assemblies, ensuring that every minute detail is accurately captured.

Additionally, resin 3D printing enables engineers to optimize their designs by quickly iterating through different versions and making necessary adjustments. This iterative process helps save time and resources, ultimately leading to more efficient product development.

Overall, resin 3D printing offers substantial benefits and has found its place in a wide range of applications, from the intricate world of jewelry making to the complex realm of engineering prototyping. Its precision, versatility, and efficiency make it an indispensable technology that continues to push the boundaries of design and manufacturing.

Challenges In Resin 3d Printing

Support Removal

Resin 3D printing involves intricate support structures that must be carefully removed to avoid damaging the print.

- Sharp tools are commonly used for support removal.

- Improper removal can lead to print distortion.

Resin Handling And Safety Precautions

Proper handling of resin is crucial due to its toxic nature.

- Always wear gloves and a mask when handling resin.

- Resin should be stored in a well-ventilated area.

Future Of Resin 3d Printing

The future of resin 3D printing holds immense potential as advancements continue to enhance the capabilities of resin 3D printers. With its high precision and ability to create intricate designs, resin 3D printing opens up new possibilities in various industries like healthcare, engineering, and manufacturing.

The technology is expected to evolve further, offering greater accessibility and affordability, making it a game-changer in the world of additive manufacturing.

Advancements In Resin Formulations

The future of resin 3D printing holds exciting possibilities. New resin formulations are enhancing printing quality and material properties. Innovations focus on durability and visual appeal of printed objects. Advanced resins offer improved strength and flexibility, expanding printing applications. Enhanced color options provide more creative freedom for designers. Resin manufacturers continue to push boundaries for higher precision and faster curing times.

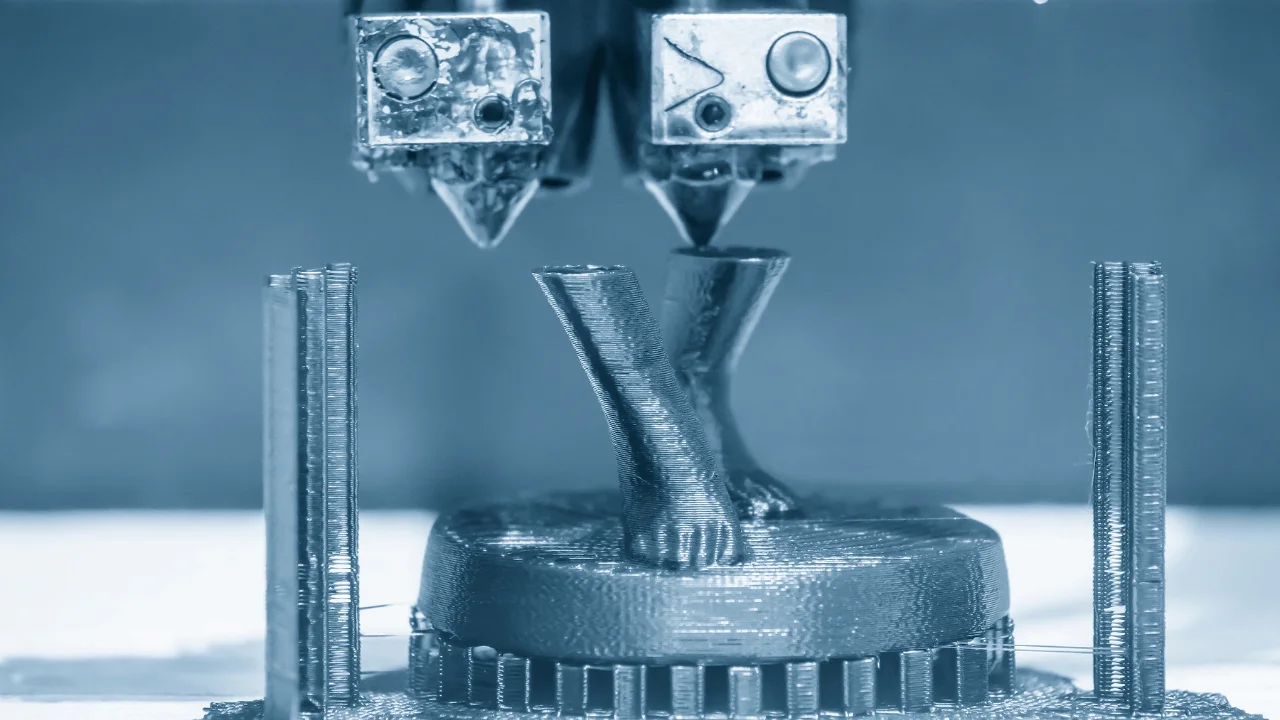

Integration With Other Manufacturing Processes

Resin 3D printing is seamlessly integrating with traditional manufacturing techniques. Hybrid processes combine the strengths of resin printing with CNC machining and injection molding. This integration optimizes production efficiency and materials usage. Customizable production tooling and prototyping benefit from the versatility of resin printing. Complex geometries and intricate designs are achievable through these integrated approaches. Manufacturers are leveraging this synergy for streamlined and cost-effective manufacturing processes.

Frequently Asked Questions Of Resin 3d Printer

A resin 3D printer is a type of 3D printer that uses liquid resin as the material for creating objects. It works by solidifying the resin layer by layer using a light source, typically a UV laser or projector. This method allows for high-resolution, detailed prints.

Resin 3D printers are known for their ability to produce highly detailed and intricately shaped objects with smooth surfaces. They are also capable of creating objects with fine features and intricate geometries that traditional FDM printers cannot achieve. Moreover, resin prints generally have a higher level of accuracy and dimensional stability.

Resin 3D printing, also known as stereolithography, works by curing liquid resin layer by layer using a light source. The printer’s build platform descends into the resin vat, and the light selectively cures the resin, solidifying it into the desired shape.

Resin 3D printers are ideal for producing small, intricately detailed objects such as jewelry, miniatures, dental models, and prototypes. The high precision and smooth surface finish make them perfect for items requiring fine detail and accuracy.

Conclusion

To sum up, the resin 3D printer is a game changer in the field of printing technology. Its ability to create highly detailed and intricate prints opens up endless possibilities for designers, artists, and innovators. With its high-quality output, speed, and user-friendly features, this printer is a valuable asset for any industry.

Embracing the resin 3D printer will undoubtedly bring innovation and efficiency to the world of printing. Experience the future of printing with the resin 3D printer today!

Check out our Blog about Smart Home product